Propane Tank Gauges

A propane tank has two gauges. Most users are familiar with the gauge that is used to read how much gas they have in their tank, which is called a face gauge, or dial gauge. This gauge indicates how many gallons of propane a tank contains, and is expressed as a percentage. The second tank gauge is what is called a fixed liquid level gauge, or "bleeder valve", which is used by delivery personnel durring this tank fill process. Each gauge plays a vital role in propane volume level and is explained below.

Tank Float Gauge - What Consumers Use

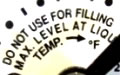

The tank gauge is for consumer use only, and while dependable, it does not show an exact amount of gas in the tank. As indicated in the picture to the left, the tank float gauge is not to be used for filling as it only gives an approximate tank percentage and cannot be considered 100% reliable. The fixed liquid level gauge is used for filling. Tanks with float gauges measure the volume of the tank as a percentage of the total capacity of the container. If the gauge reads 50% on a 250 gallon propane tank, the tank has approximately, 125 gallons of propane. Many people think this is a pressure gauge or a gallons gauge (although some older tanks do have gallons gauges) but it is a gauge that indicates the volume in the tank as a percentage of the tank's total capacity.

Propane Gauge Operation

The float gauge in a propane tank consists of moving parts located both inside the tank and outside. At the end of the stem is the float (pictured below) that rises and falls with the level of the propane in the tank. The top of the stem is the pinion gear (pictured left) that turns the gear in the shaft and causes the dial on the external face gauge to turn. As stated above, the tank float gauge is not considered a fully reliable instrument for measuring tank volume. Propane tank gauges have a number of moving parts that are subject to wear and tear and can also become ineffective in any part of the assembly. If the gauge needs to be replaced, the propane tank must be empty. If the tank face gauge has a stuck dial, it can be quickly replaced as dial/face gauges use magnets and can be interchanged without the tank needing to be empty.

Propane Percentage Gauge Converted to Gallons

To convert percentage to gallons, multiply the number displayed on the tank gauge (50 means 50% or .50) by the water capacity of the tank. Water capacity can be found on the tank manufacturers nameplate. The tank gauge percentage chart indicates percentages converted to gallons on common size propane tanks (at 60°F).

Fixed Liquid Level Gauge - Bleeder Valve

The fixed liquid level indicator, used only when filling a tank, also called the bleeder valve is the one and only gauging device that accurately depicts the level of propane in the tank when it is being filled. The tank gauge is not to be used during the refilling process. This section will explain why the bleeder valve is open during the refueling process. Many people believe that using the fixed liquid level gauge during gas delivery results in a large amount of lost propane. Even if two cubic feet of propane gas is lost through the bleeder valve, this is only .05 gallons of gas. At $2.00 per gallon, this would be equal to ten cents worth of propane expelled through the bleeder valve.

Understanding Bleeder Valves

The bleeder valve is designed so that during the filling process, when the propane going into the tank reaches 80%, liquid will come out of the opened valve. This lets the delivery driver know that the tank has reached its maximum filling capacity. The valve is connected to what is called a dip tube that goes into the container. The dip tube is fixed and set at length equal to 80% liquid level tank capacity. In other words, the tip of the dip tube is at the level equal to the container being 80% full. The dip tube itself should always be located in the vapor space and never submerged in liquid propane.

Fixed Liquid Level Gauge Valve Operation

In simple terms, the fixed liquid level indicator tells the person delivering the propane that the tank is at the maximum safe capacity. The picture to the left is of a service valve with the dip tube protruding from the bottom. When installed by the tank manufacturer, the dip tube is pre-set to indicate when the tank is legally full during the filling process.

Think of it this way: When drinking a soda through a straw, you will not be able to get soda through the straw if the tip of the straw is above the level of the soda. When the tip of the straw is in the soda, you are able to drink the soda. A dip tube works along the same principal as a straw.